OIL EXTRACTION TECHNOLOGY TODAY

From washing the olives to extracting the oil: the process today.

The traditional hydraulic pressure extraction method is no longer able to meet the quality, hygiene and safety requirements of modern oil extraction technology. For this reason a new centrifugation method was devised, which is taking the place of traditional machinery.

This brief comparison between the two processes can explain how the final product is affected.

HYDRAULIC PRESSURE METHOD

CRUSHING

After discarding the larger twigs, the olives go in the molazza (millstone), where two large granite wheels crush and mix them, producing olive paste.

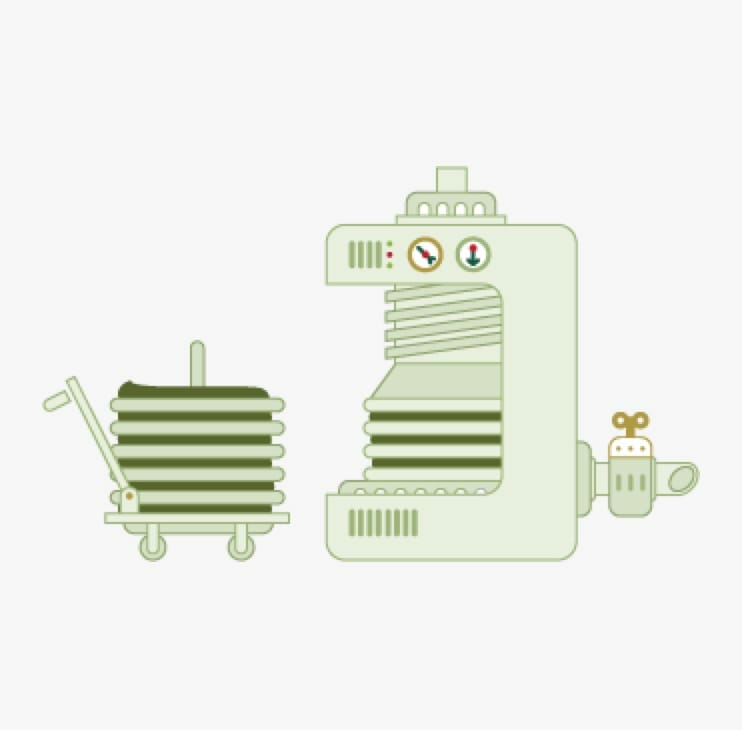

OIL EXTRACTION

The olive paste is placed on discs of woven nylon fibres, called fiscoli, with a dispensing machine. Then, the fiscoli are placed in a powerful hydraulic press which allows the extraction of the oil and the vegetation water from the pomace.

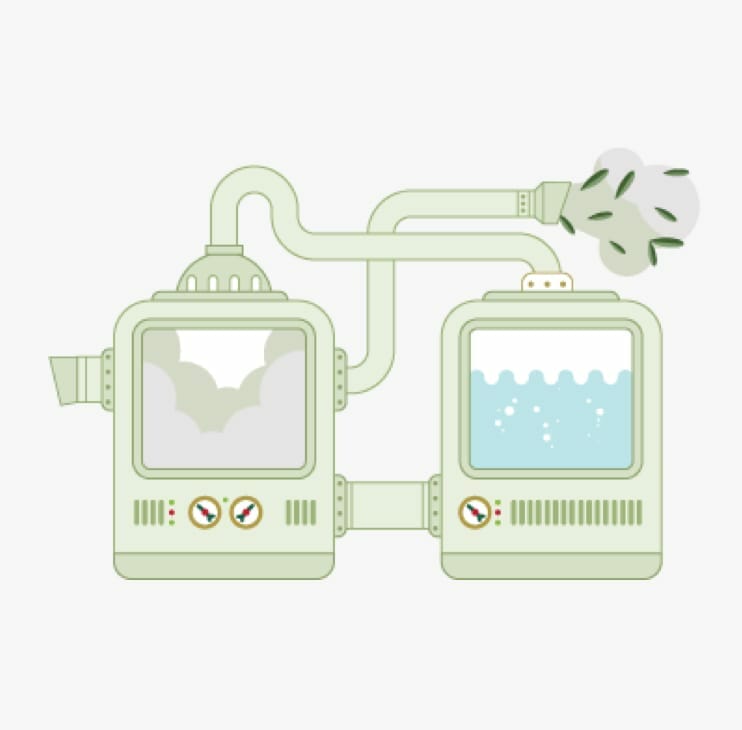

CENTRIFUGATION

While traditionally oil was separated from the vegetation water by decantation, today centrifuges are used even in pressure systems.

CENTRIFUGATION

LEAF REMOVAL AND WASHING

Olives are cleaned from twigs and leaves by suction, as they would otherwise give the oil an unpleasant bitter taste. Then olives are washed to get rid of soil and other impurities.

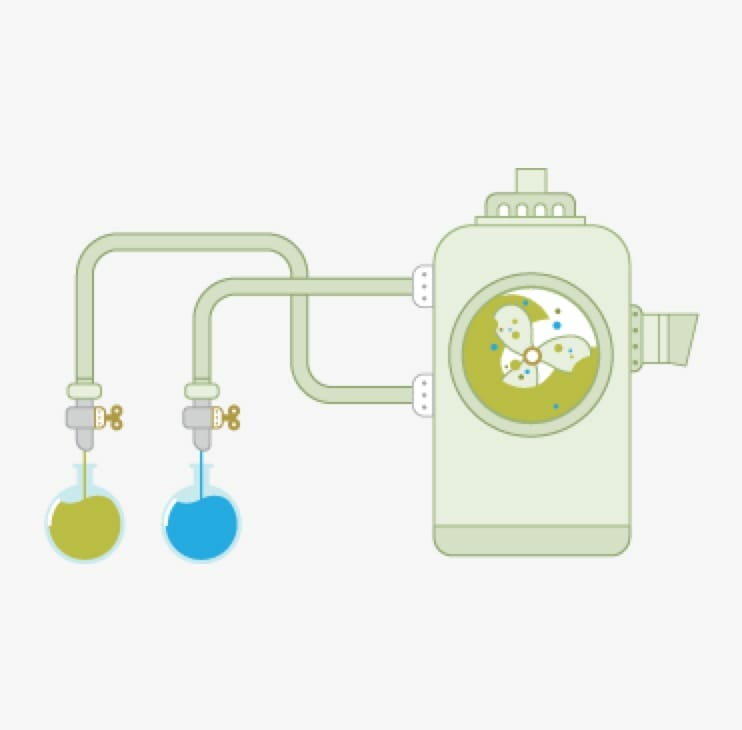

CRUSHING AND MALAXING

The clean olives go in a powerful centrifuge that makes them into a smooth paste.

In the following phase, called malaxation, the oil particles combine into bigger droplets, preparing the paste for the next phase – oil separation.

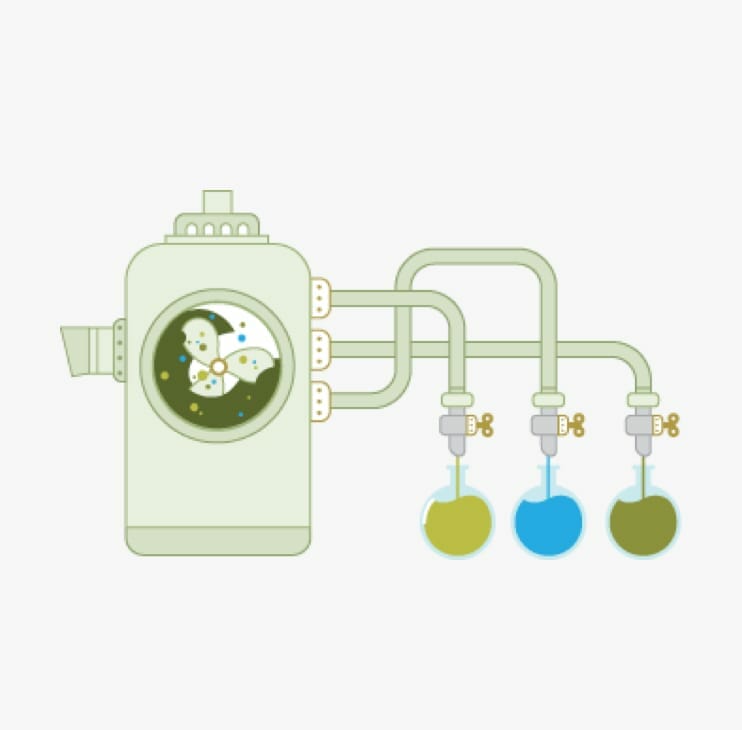

CENTRIFUGATION

The paste goes in a horizontal centrifuge, or decanter, which divides the oil from the pomace and the vegetation water. It will then pass through a second centrifuge, which dries it further, ensuring a better preservation of the product.